How Industrial Inspectors Benefit from Pressure Vessel Software

Industrial inspectors play a crucial role in ensuring the safety and compliance of pressure vessels. These inspectors, whether working for Notified Bodies under the Pressure Equipment Directive 2014/68/EU (PED) or acting as certifying engineers for ASME U-stamp procedures, must meticulously verify the calculations provided by manufacturers. This validation is a key step before granting approval for construction, ensuring that the vessels meet stringent regulatory and safety standards. The current article examines the role of pressure vessel software in industrial inspections.

Why inspectors also use software

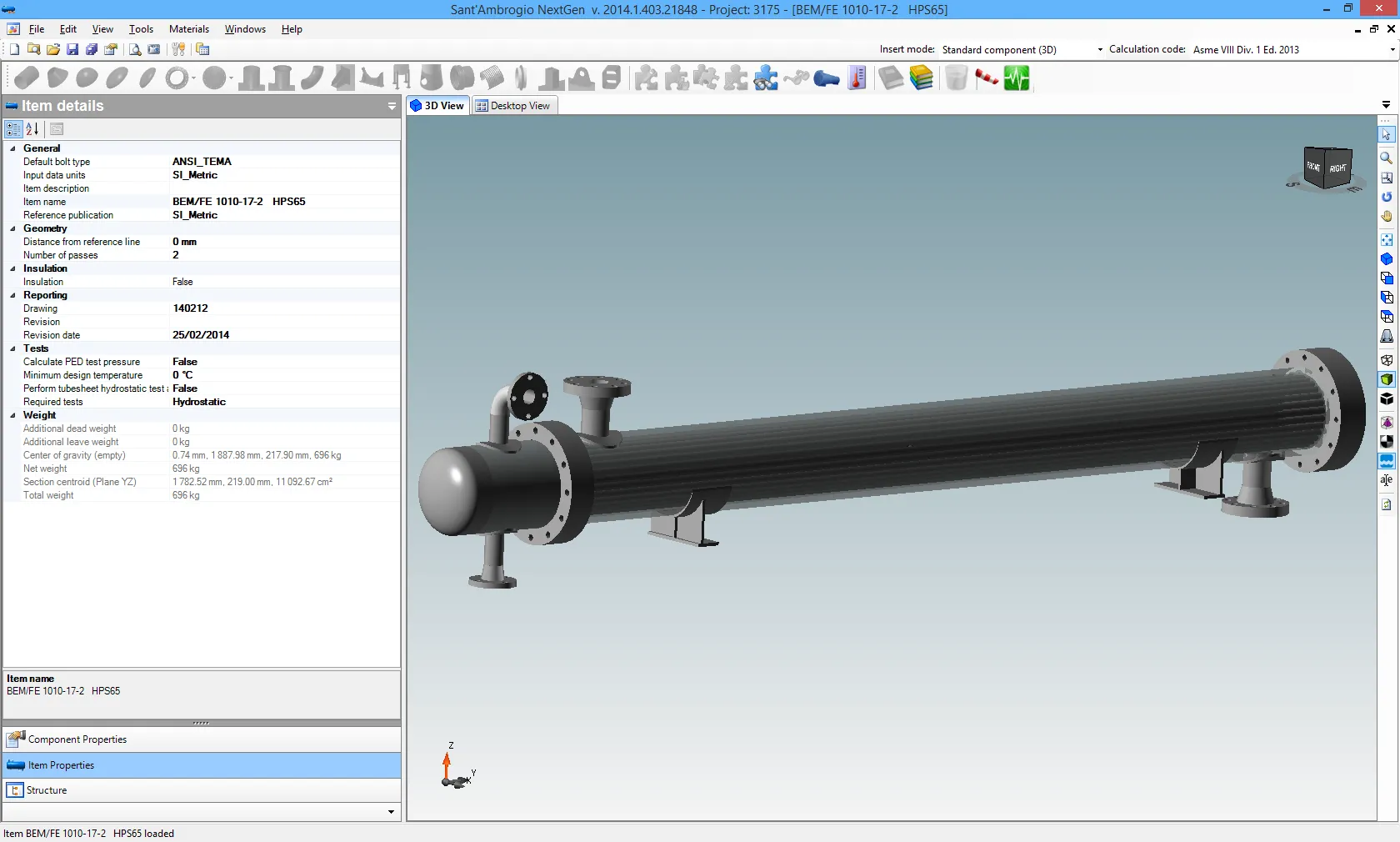

To verify manufacturer calculations efficiently, inspectors rely on pressure vessel analysis software. These programs enable them to cross-check values, confirm compliance with industry standards, and identify potential calculation errors that could lead to unsafe designs.

Hand calculations, while possible, are time-consuming and prone to human error, especially for complex vessel designs. Software automates these calculations, ensuring accuracy and compliance with regulatory standards. Additionally, inspectors often use different software than manufacturers to maintain independent verification, avoiding biases and confirming that calculations adhere to industry requirements.

Rather than rebuilding the entire vessel model, inspectors focus on critical calculations, such as wall thickness, stress analysis, and pressure ratings, to detect potential discrepancies. Thus, unlike manufacturers, who use such software continuously throughout the design and fabrication process, inspectors only need access to these tools intermittently—typically during the review and approval phases.

The licensing challenge

Most software solutions currently available operate on an annual licensing model. This arrangement may work well for manufacturers who use the software regularly, but it is not cost-effective for inspectors who require it only for short periods. The high cost of a yearly license can be prohibitive, forcing inspectors to either seek alternative, less efficient validation methods or rely on third-party verification services, which can introduce delays and additional costs.

A new solution is required

Recognizing this gap in the market, a monthly licensing model tailored to the specific needs of industrial inspectors should be considered. This innovation will allow inspectors to access high-quality software only when needed, significantly reducing costs while maintaining the accuracy and efficiency of their verification process.

Conclusion

The role of industrial inspectors is vital in maintaining the integrity of pressure vessels, and having the right tools at the right time is essential. The traditional annual licensing model for calculation software does not align with the sporadic usage patterns of inspectors, creating unnecessary financial and operational inefficiencies. Newly developed software named VCLAVIS.com offers short-term licensing options, ensuring that inspectors can perform their crucial work without the financial burden of an annual commitment. This not only streamlines the approval process for pressure vessel manufacturing but also enhances compliance with PED and ASME standards.